Anyone who works in the medical device industry knows that there are numerous requirements you have to follow along the way. Needless to say, this goes for all industries, the topic of this article is related to medical devices.

When it comes to requirements, there is a large number of them within all aspects of this industry. In this article, we will talk about design control. The following video is a part of our online Design Control for Medical Devices course, and, unlike this article which covers the basics, it explains the matter in depth.

First things first: design control is the name for the requirements on product development that you have to meet to sell a medical device to the US market.

As to why you should care, there are several answers.

Clearly, and in simple words, complying with design control requirements is a regulatory requirement. But, if you’re working with medical devices, it means that you’re directly connected to people’s health and wellbeing. In that case, doing something important just because you have to do it for the sake of the law is…just wrong. Also, working according to design control requirements is an effective way of creating products, that are not only safe, but that will also satisfy your customer’s needs.

It’s interesting to note that there are industries where these requirements are not obligatory. Still, many of these industries follow design control requirements simply because they represent best practices in developing new products.

Design control is the area of requirements from the US Quality System Regulation or QSR, that apply to the design and development of medical devices. To be even more specific, it is sub-part C of the QSR and clause 820.30 that is called Design control. As far as the European context is concerned, that would be Design and Development, and the requirements relating to that area can be found in section 7.3 of the ISO 13485 standard.

In the US there is a regulation called 21 CFR 820, or Quality system regulation (QSR) that establishes requirements for manufacturers that want to sell their products in the US market. In the European Union, there are currently three directives that cover regular medical devices, active implantable medical devices, and in-vitro diagnostic medical devices. These directives share a lot of requirements.

In addition to this, most manufacturers would also comply with the requirements of the ISO 13485 standard on quality management systems. The reason for that being that the standard contains more detailed requirements on the quality management system than the medical device directive does.

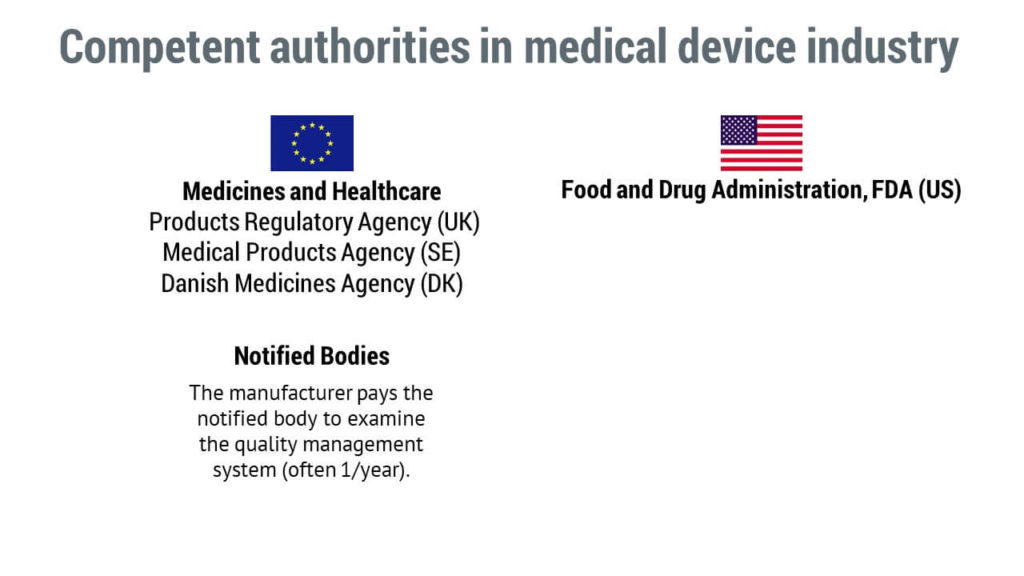

In the EU, each country has a supervising government entity for medical devices, and they are called competent authorities:

When selling to the EU, the competent authorities will usually not show up at your doorstep, unless something really bad happens. This is because the auditing of medical device manufacturers is mostly done by companies that have earned the status of being notified bodies. They will come several times a year, and you will pay them since you are their customer. For the US market, the FDA does most of the auditing itself, but FDA is likely to show up more rarely than notified bodies.

Get instant access to our online Design Control for Medical Devices course right here. In 6 hours, you can learn more about how to develop new medical devices and maintain them in organisations where design control requirements apply. This course is taken by quality assurance, project management, design engineering or those involved in R&D and product development teams.

Peter Sebelius is a highly esteemed trainer, consultant and entrepreneur in the medical device industry. He is a member of the Joint Working Group that is revising the ISO 13485 and ISO 14971 standards.

He has vast ‘hands on’ experience, having developed, amongst other things, a mechanical chest compression device and an ex vivo perfusion machine for lungs. He has received numerous awards including the Great Design Award and the title “This year’s specialist” by Veckans affärer.

Receive FREE templates and quarterly updates on upcoming courses that can help you in your career! Subscribe to our newsletter now.

When you submit this form, you will be sending personal information to medicaldevicehq.com. To comply with GDPR requirements, we need your consent to store and use the personal data you submit. Take a look at our Privacy policy for more details.